Bonding Machine in Fashion Production: The Ultimate Solution for Perfect Seams

Bonding Machine in Fashion Production: The Ultimate Solution for Perfect Seams

Bonding machines are becoming increasingly popular in the fashion industry thanks to their ability to create smooth, strong and aesthetically pleasing seams. Compared to traditional sewing methods, bonding machines offer many outstanding advantages, helping to improve production efficiency and product quality.

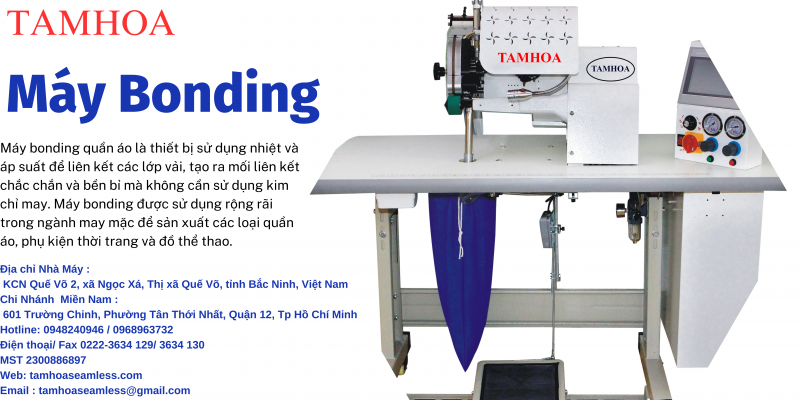

Image: Bonding Machine

Advantages of bonding machine in fashion production:

- Smooth, beautiful seams: The bonding machine uses heat and pressure to bond fabric layers, creating smooth, flat seams without excess threads, making the product more luxurious and sophisticated.

- High durability: The bond created by the bonding machine is highly durable, can withstand tensile and tearing forces well, helping the product to be more durable and beautiful over time.

- Waterproof: Some bonding machines are capable of creating waterproof seams, making the product suitable for rain and beach wear.

- Increased productivity: The bonding machine operates automatically at high speed, saving time and labor for production, increasing labor productivity.

- Minimize sewing errors: Bonding machines help minimize human sewing errors, ensuring consistent product quality.

Application of bonding machine in fashion production:

- Bonding of garment parts: Bonding machine is used to bond garment parts such as body, sleeves, collar, etc., giving the finished shape to the product.

- Creating decorative seams: Bonding machines can create beautiful decorative seams on products, adding to the aesthetics of the garment.

- Bonding different fabrics: The bonding machine can bond different fabrics such as cotton, linen, polyester, leather, etc., helping to create unique and creative products.

Notes when using bonding machines in fashion production:

- Choose the right bonding machine: You need to choose the right bonding machine for the type of fabric to be bonded, the size of the product and the needs of use.

- Adjust the temperature and pressure appropriately: It is necessary to adjust the temperature and pressure appropriately for each type of fabric to ensure the quality of the seam.

- Clean the machine regularly: The machine needs to be cleaned regularly to ensure efficient and durable operation.

Using bonding machines effectively will help you improve product quality, increase labor productivity and save production costs. Bonding machines are an indispensable tool in the modern fashion manufacturing industry.

Tam Hoa Technical Company Limited

Factory Address: Que Vo 2 Industrial Park, Ngoc Xa Commune, Que Vo Town, Bac Ninh Province, Vietnam

Southern Branch: 601 Truong Chinh, Tan Thoi Nhat Ward, District 12, Ho Chi Minh City

Hotline: 0948240946 / 0968963732

Phone/Fax 0222-3634 129/ 3634 130

MST 2300886897

Web: tamhoaseamless.com

Email: [email protected]